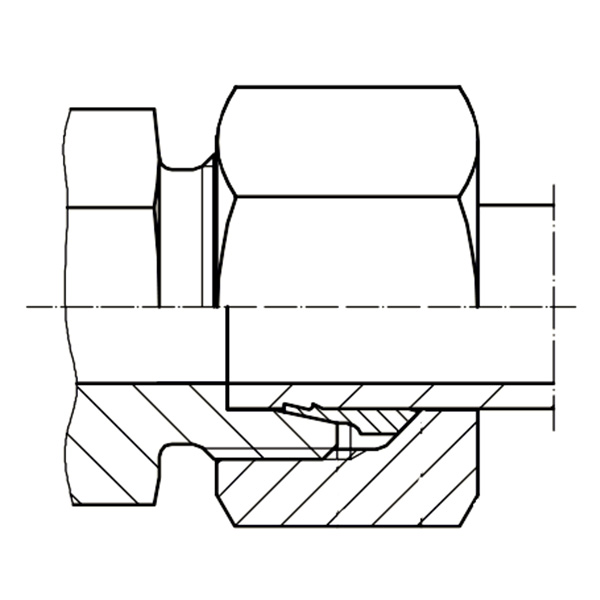

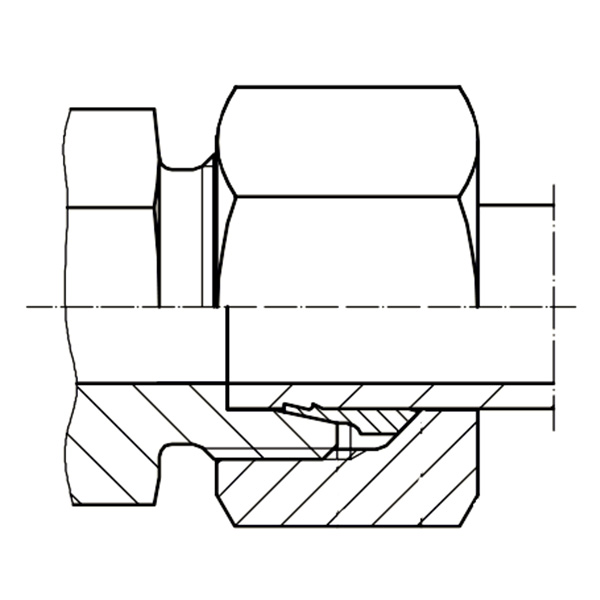

24 degree cone connector

Nut and Sleeve

| Availability: | |

|---|---|

| PDF Export | |

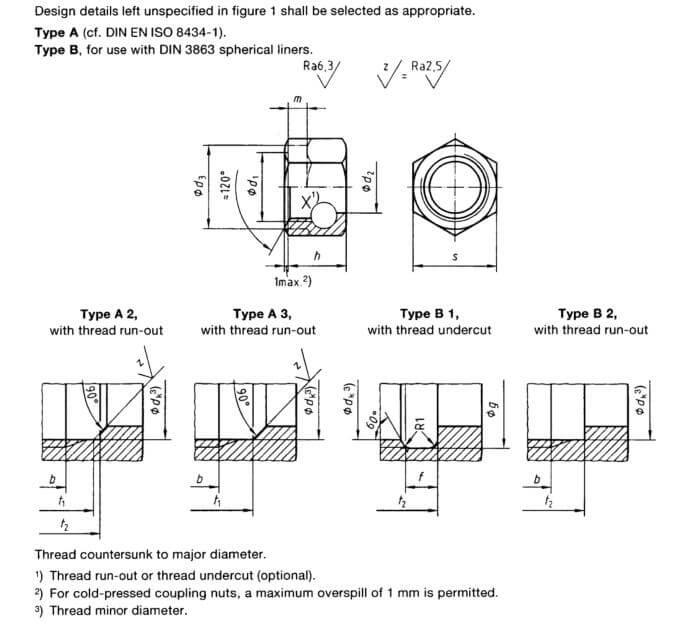

Introduction Of Tube Nut

Tube nuts is used for pushing the cutting ring bite into hydraulic tube, connecting the adapter fittings, it has different symbols such as ISO “N”, Parker “M”, Winner”NL/NS” etc, it is also coupling nuts and union nut.. We also provide wire nut and customized nut for your different need.

Assembly Of Tube Nut

The nut for pushing the front and second (two)edge to cut(double bite) the designed depth into the tube, with the correct torque of wrench, do it in the instruction of fittings assembly.

Standards Of Tube Nut

Products meet standard of DIN 3870(LL series), DIN 2353 and ISO 8434-1.

Finish is 72 hours without surface coating corrosion acc.to ISO 9227 Fe/Zn8/Cn/T0(T2).

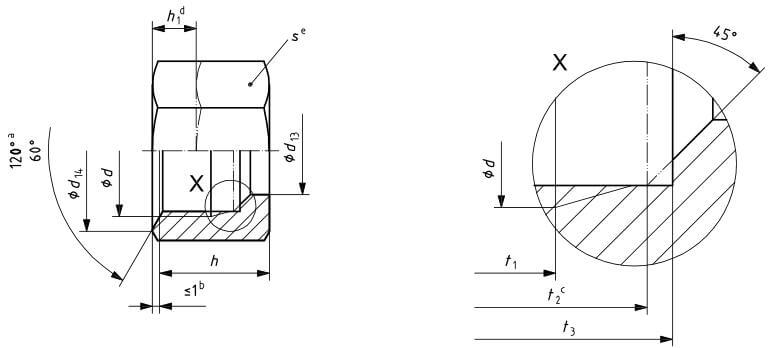

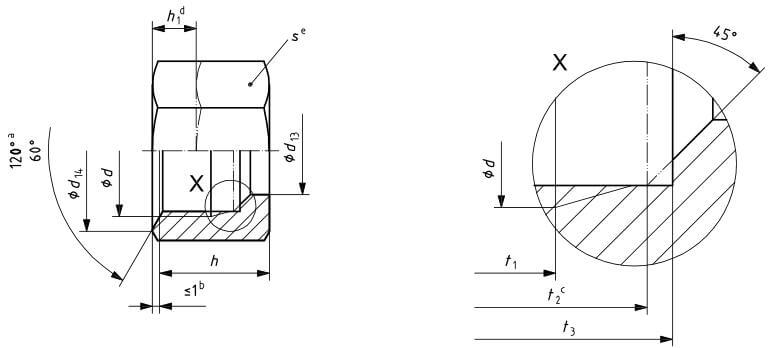

Design of Tube Nut

ISO 8434-1 is instead of DIN 3870 design of tube nut, nuts should be made of carbon steel, stainless steel and copper alloy, to be used with correspond to the fitting bodies.

Raw Material types of DIN tube nut

They are either cold formed, hot formed or machined from cold drawn, it is based on different size for right material shapes.

Dimensions of nuts from ISO 8434-1(DIN3870)

| Series | Tube OD | Thread d | d13 B11 | d14 ref. | 11 min. | h +0.5 -0.2 | h1 ±1 | s | t2 0 +0.2 | t3 0 +0.2 |

| LL | 4 | M8×1 | 4 | 9.8 | 5 | 11 | 3.5 | 10 | 7.5 | 8 |

| 5 | M10×1 | 5 | 11.8 | 5.5 | 11.5 | 3.5 | 12 | 7.8 | 8.5 | |

| 6 | M10×1 | 6 | 11.8 | 5.5 | 11.5 | 3.5 | 12 | 8.2 | 8.5 | |

| 8 | M12×1 | 8 | 13.8 | 6 | 12 | 3.5 | 14 | 8.7 | 9 | |

| L | 6 | M12×1.5 | 6 | 13.8 | 7 | 14.5 | 4 | 14 | 10 | 10.5 |

| 8 | M14×1.5 | 8 | 16.8 | 7 | 14.5 | 4 | 17 | 10 | 10.5 | |

| 10 | M16×1.5 | 10 | 18.8 | 8 | 15.5 | 4 | 19 | 11 | 11.5 | |

| 12 | M18×1.5 | 12 | 21.8 | 8 | 15.5 | 5 | 22 | 11 | 11.5 | |

| 15 | M22×1.5 | 15 | 26.8 | 8.5 | 17 | 5 | 27 | 11.5 | 12.5 | |

| 18 | M26x1.5 | 18 | 31.8 | 8.5 | 18 | 5 | 32 | 11.5 | 13 | |

| 22 | M30×2 | 22 | 35.8 | 9.5 | 20 | 7 | 36 | 13.5 | 14.5 | |

| 28 | M36×2 | 28 | 40.8 | 10 | 21 | 7 | 41 | 14 | 15 | |

| 35 | M45×2 | 35.3 | 49.8 | 12 | 24 | 8 | 50 | 16 | 17 | |

| 42 | M52×2 | 42.3 | 59.6 | 12 | 24 | 8 | 60 | 16 | 17 | |

| S | 6 | M14×1.5 | 6 | 16.8 | 8.5 | 16.5 | 5 | 17 | 11 | 12.5 |

| 8 | M16×1.5 | 8 | 18.8 | 8.5 | 16.5 | 5 | 19 | 11 | 12.5 | |

| 10 | M18×1.5 | 10 | 21.8 | 8.5 | 17.5 | 5 | 22 | 11 | 12.5 | |

| 12 | M20×1.5 | 12 | 23.8 | 8.5 | 17.5 | 5 | 24 | 11 | 12.5 | |

| 16 | M24×1.5 | 16 | 29.8 | 10.5 | 20.5 | 6 | 30 | 13 | 14.5 | |

| 20 | M30x2 | 20 | 35.8 | 12 | 24 | 8 | 36 | 15.5 | 17 | |

| 25 | M36×2 | 25 | 45.8 | 14 | 27 | g | 46 | 17 | 19 | |

| 30 | M42×2 | 30 | 49.8 | 15 | 29 | 10 | 50 | 18 | 20 | |

| 38 | M52×2 | 38.3 | 59.6 | 17 | 32.5 | 10 | 6o | 19.5 | 22.5 |

When it comes to hydraulic systems, connections are everything. This DIN tube nut proves the claim as a crucial fitting for the flawless functioning of hydraulic tubes that stand up to the demands of thermally unstable and corrosive environments.

The noteworthy features and functions of this nut include:

Connective stability. This nut tube fitting is an essential link between hydraulic components. Its primary function is to guide the cutting ring into the hydraulic tube for a dependable and leak-free connection.

Compliance and versatility. Industry-wise, this nut is a compliant solution for your fastening needs. It can work with a myriad of adapters and fittings under the ISO 8434-1 and DIN 3870 standards.

Multi-functional design. Beyond its role as a tube fitting, it can also double as a coupling and union nut. This enhances its utility in hydraulic applications and makes it easier to kick your assemblies with double-bite cutting rings up a notch.

Material options. Fitsch is an independent supplier of Parker hydraulic fittings, adapters, and DIN nuts in particular. That means you can directly request your hardware to be made of carbon steel for extraordinary robustness that would underpin hydraulic applications where high tensile strength is required or stainless steel for longevity protected against corrosive risks.

Superior finishes. To add to the performance and longevity of this nut, you can opt for a zinc-plated version or a Zn-Ni coating. The latter proves to be more dependable when exposed to higher thermal stresses and more aggressive corrosive environments, extending the life of your connections and the hydraulic assembly they serve.

Your projects are not those to be postponed. With Fitsch, the desired surface coating can be implemented within just 72 hours. We leave no stone unturned and no thread element unchecked.

This DIN nut comes in globally recognized series, including LL, L, and S, each made for different thread types and OD dimensions. To check out technical specifications, inquire directly or navigate to the Related Document section to download PDFs. They will guide you through the series, threads, weight, DIN criteria, and other essential characteristics.

Once you are ready to incorporate the nut into your systems, Fitsch specialists are at your service. Buy Parker hydraulic adapters online, choose the perfect nut type, and select the preferred finish. Precision engineering and lightning-fast delivery are on us.

Introduction Of Tube Nut

Tube nuts is used for pushing the cutting ring bite into hydraulic tube, connecting the adapter fittings, it has different symbols such as ISO “N”, Parker “M”, Winner”NL/NS” etc, it is also coupling nuts and union nut.. We also provide wire nut and customized nut for your different need.

Assembly Of Tube Nut

The nut for pushing the front and second (two)edge to cut(double bite) the designed depth into the tube, with the correct torque of wrench, do it in the instruction of fittings assembly.

Standards Of Tube Nut

Products meet standard of DIN 3870(LL series), DIN 2353 and ISO 8434-1.

Finish is 72 hours without surface coating corrosion acc.to ISO 9227 Fe/Zn8/Cn/T0(T2).

Design of Tube Nut

ISO 8434-1 is instead of DIN 3870 design of tube nut, nuts should be made of carbon steel, stainless steel and copper alloy, to be used with correspond to the fitting bodies.

Raw Material types of DIN tube nut

They are either cold formed, hot formed or machined from cold drawn, it is based on different size for right material shapes.

Dimensions of nuts from ISO 8434-1(DIN3870)

| Series | Tube OD | Thread d | d13 B11 | d14 ref. | 11 min. | h +0.5 -0.2 | h1 ±1 | s | t2 0 +0.2 | t3 0 +0.2 |

| LL | 4 | M8×1 | 4 | 9.8 | 5 | 11 | 3.5 | 10 | 7.5 | 8 |

| 5 | M10×1 | 5 | 11.8 | 5.5 | 11.5 | 3.5 | 12 | 7.8 | 8.5 | |

| 6 | M10×1 | 6 | 11.8 | 5.5 | 11.5 | 3.5 | 12 | 8.2 | 8.5 | |

| 8 | M12×1 | 8 | 13.8 | 6 | 12 | 3.5 | 14 | 8.7 | 9 | |

| L | 6 | M12×1.5 | 6 | 13.8 | 7 | 14.5 | 4 | 14 | 10 | 10.5 |

| 8 | M14×1.5 | 8 | 16.8 | 7 | 14.5 | 4 | 17 | 10 | 10.5 | |

| 10 | M16×1.5 | 10 | 18.8 | 8 | 15.5 | 4 | 19 | 11 | 11.5 | |

| 12 | M18×1.5 | 12 | 21.8 | 8 | 15.5 | 5 | 22 | 11 | 11.5 | |

| 15 | M22×1.5 | 15 | 26.8 | 8.5 | 17 | 5 | 27 | 11.5 | 12.5 | |

| 18 | M26x1.5 | 18 | 31.8 | 8.5 | 18 | 5 | 32 | 11.5 | 13 | |

| 22 | M30×2 | 22 | 35.8 | 9.5 | 20 | 7 | 36 | 13.5 | 14.5 | |

| 28 | M36×2 | 28 | 40.8 | 10 | 21 | 7 | 41 | 14 | 15 | |

| 35 | M45×2 | 35.3 | 49.8 | 12 | 24 | 8 | 50 | 16 | 17 | |

| 42 | M52×2 | 42.3 | 59.6 | 12 | 24 | 8 | 60 | 16 | 17 | |

| S | 6 | M14×1.5 | 6 | 16.8 | 8.5 | 16.5 | 5 | 17 | 11 | 12.5 |

| 8 | M16×1.5 | 8 | 18.8 | 8.5 | 16.5 | 5 | 19 | 11 | 12.5 | |

| 10 | M18×1.5 | 10 | 21.8 | 8.5 | 17.5 | 5 | 22 | 11 | 12.5 | |

| 12 | M20×1.5 | 12 | 23.8 | 8.5 | 17.5 | 5 | 24 | 11 | 12.5 | |

| 16 | M24×1.5 | 16 | 29.8 | 10.5 | 20.5 | 6 | 30 | 13 | 14.5 | |

| 20 | M30x2 | 20 | 35.8 | 12 | 24 | 8 | 36 | 15.5 | 17 | |

| 25 | M36×2 | 25 | 45.8 | 14 | 27 | g | 46 | 17 | 19 | |

| 30 | M42×2 | 30 | 49.8 | 15 | 29 | 10 | 50 | 18 | 20 | |

| 38 | M52×2 | 38.3 | 59.6 | 17 | 32.5 | 10 | 6o | 19.5 | 22.5 |

When it comes to hydraulic systems, connections are everything. This DIN tube nut proves the claim as a crucial fitting for the flawless functioning of hydraulic tubes that stand up to the demands of thermally unstable and corrosive environments.

The noteworthy features and functions of this nut include:

Connective stability. This nut tube fitting is an essential link between hydraulic components. Its primary function is to guide the cutting ring into the hydraulic tube for a dependable and leak-free connection.

Compliance and versatility. Industry-wise, this nut is a compliant solution for your fastening needs. It can work with a myriad of adapters and fittings under the ISO 8434-1 and DIN 3870 standards.

Multi-functional design. Beyond its role as a tube fitting, it can also double as a coupling and union nut. This enhances its utility in hydraulic applications and makes it easier to kick your assemblies with double-bite cutting rings up a notch.

Material options. Fitsch is an independent supplier of Parker hydraulic fittings, adapters, and DIN nuts in particular. That means you can directly request your hardware to be made of carbon steel for extraordinary robustness that would underpin hydraulic applications where high tensile strength is required or stainless steel for longevity protected against corrosive risks.

Superior finishes. To add to the performance and longevity of this nut, you can opt for a zinc-plated version or a Zn-Ni coating. The latter proves to be more dependable when exposed to higher thermal stresses and more aggressive corrosive environments, extending the life of your connections and the hydraulic assembly they serve.

Your projects are not those to be postponed. With Fitsch, the desired surface coating can be implemented within just 72 hours. We leave no stone unturned and no thread element unchecked.

This DIN nut comes in globally recognized series, including LL, L, and S, each made for different thread types and OD dimensions. To check out technical specifications, inquire directly or navigate to the Related Document section to download PDFs. They will guide you through the series, threads, weight, DIN criteria, and other essential characteristics.

Once you are ready to incorporate the nut into your systems, Fitsch specialists are at your service. Buy Parker hydraulic adapters online, choose the perfect nut type, and select the preferred finish. Precision engineering and lightning-fast delivery are on us.

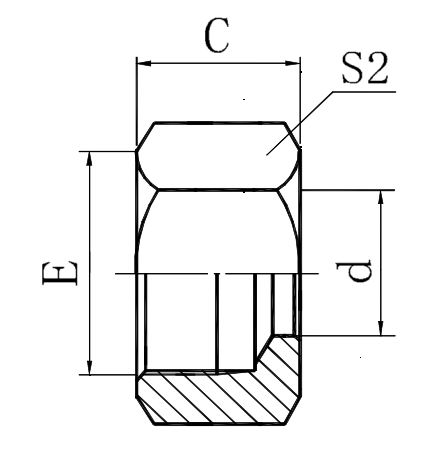

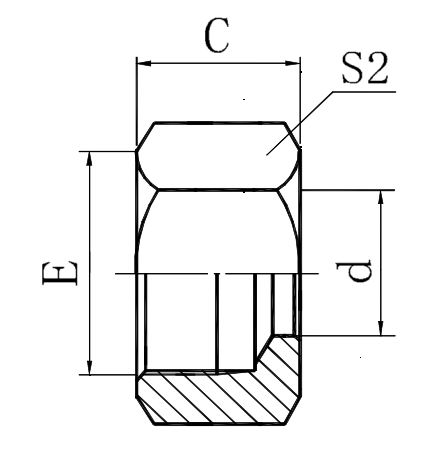

Catalogue Of DIN Tube Nut

NLL/NL/NS

Tube Nut/Union Nut REF: ISO 8434-1/ DIN 3861

PART NO. | THERAD E | DIMENSIONS | Cross reference | Weight g/1 piece | Min. tube wall thickness | Final assembly [Nm] or 30° | |||

d | C | S2 | Parker PN | ISO 8434-1 | |||||

LL SERIE | |||||||||

NLL-08 | M8×1 | 4 | 11 | 10 | M04LL | N04LM8 | 4 | ||

NLL-10 | M10×1 | 6 | 11.5 | 12 | M06LL | N06LM10 | 6 | ||

NLL-12 | M12×1 | 8 | 12 | 14 | M08LL | N08LM12 | 7 | ||

NLL-14 | M14×1 | 10 | 12.5 | 17 | M10LL | N10LM14 | 11 | ||

NLL-16 | M16×1 | 12 | 13 | 19 | M12LL | N12LM16 | 13 | ||

L SERIE | |||||||||

NL-12 | M12X1.5 | 6 | 14.5 | 14 | M06L | N06LM12 | 10 | 6x1 | 25 |

NL-14 | M14X1.5 | 8 | 14.5 | 17 | M08L | N08LM14 | 15 | 8x1 | 40-45 |

NL-16 | M16X1.5 | 10 | 15.5 | 19 | M10L | N10LM16 | 18 | 10x1 | 50-55 |

NL-18 | M18X1.5 | 12 | 15.5 | 22 | M12L | N12LM18 | 25 | 12x1.5 | 70-80 |

NL-22 | M22X1.5 | 15 | 17 | 27 | M15L | N15LM22 | 42 | 15x1.5 | 90-100 |

NL-26 | M26X1.5 | 18 | 18 | 32 | M18L | N18LM26 | 62 | 18x1.5 | 115-150 |

NL-30 | M30X2 | 22 | 20 | 36 | M22L | N22LM30 | 82 | 22x2 | 200-210 |

NL-36 | M36X2 | 28 | 21 | 41 | M28L | N28LM36 | 89 | 28x2 | 250-310 |

NL-45 | M45X2 | 35 | 24 | 50 | M35L | N35LM45 | 137 | 35x3 | 400-500 |

NL-52 | M52X2 | 42 | 24 | 60 | M42L | N42LM52 | 216 | 42x3 | 500-600 |

S SERIE | |||||||||

NS-14 | M14X1.5 | 6 | 16.5 | 17 | M06S | N06SM14 | 17 | 6x2 | 35-45 |

NS-16 | M16X1.5 | 8 | 16.5 | 19 | M08S | N08SM16 | 20 | 8x1.5 | 55-60 |

NS-18 | M18X1.5 | 10 | 17.5 | 22 | M10S | N10SM18 | 31 | 10x1.5 | 70-80 |

NS-20 | M20X1.5 | 12 | 17.5 | 24 | M12S | N12SM20 | 34 | 12x1.5 | 85-100 |

NS-22 | M22X1.5 | 14 | 20.5 | 27 | M14S | N14SM22 | 53 | 14x2 | 110-135 |

NS-24 | M24X1.5 | 16 | 20.5 | 30 | M16S | N16SM24 | 66 | 16x1.5 | 120-150 |

NS-30 | M30X2 | 20 | 24 | 36 | M20S | N20SM30 | 102 | 20x2 | 200-250 |

NS-36 | M36X2 | 25 | 27 | 46 | M25S | N25SM36 | 202 | 25x2.5 | 340-400 |

NS-42 | M42X2 | 30 | 29 | 50 | M30S | N30SM42 | 219 | 30x3 | 480-500 |

NS-52 | M52X2 | 38 | 32.5 | 60 | M38S | N38SM52 | 339 | 38x4 | 600-850 |

NOTE: If order stainless steel please add SS after part no, ie NL-06SS.

Catalogue Of DIN Tube Nut

NLL/NL/NS

Tube Nut/Union Nut REF: ISO 8434-1/ DIN 3861

PART NO. | THERAD E | DIMENSIONS | Cross reference | Weight g/1 piece | Min. tube wall thickness | Final assembly [Nm] or 30° | |||

d | C | S2 | Parker PN | ISO 8434-1 | |||||

LL SERIE | |||||||||

NLL-08 | M8×1 | 4 | 11 | 10 | M04LL | N04LM8 | 4 | ||

NLL-10 | M10×1 | 6 | 11.5 | 12 | M06LL | N06LM10 | 6 | ||

NLL-12 | M12×1 | 8 | 12 | 14 | M08LL | N08LM12 | 7 | ||

NLL-14 | M14×1 | 10 | 12.5 | 17 | M10LL | N10LM14 | 11 | ||

NLL-16 | M16×1 | 12 | 13 | 19 | M12LL | N12LM16 | 13 | ||

L SERIE | |||||||||

NL-12 | M12X1.5 | 6 | 14.5 | 14 | M06L | N06LM12 | 10 | 6x1 | 25 |

NL-14 | M14X1.5 | 8 | 14.5 | 17 | M08L | N08LM14 | 15 | 8x1 | 40-45 |

NL-16 | M16X1.5 | 10 | 15.5 | 19 | M10L | N10LM16 | 18 | 10x1 | 50-55 |

NL-18 | M18X1.5 | 12 | 15.5 | 22 | M12L | N12LM18 | 25 | 12x1.5 | 70-80 |

NL-22 | M22X1.5 | 15 | 17 | 27 | M15L | N15LM22 | 42 | 15x1.5 | 90-100 |

NL-26 | M26X1.5 | 18 | 18 | 32 | M18L | N18LM26 | 62 | 18x1.5 | 115-150 |

NL-30 | M30X2 | 22 | 20 | 36 | M22L | N22LM30 | 82 | 22x2 | 200-210 |

NL-36 | M36X2 | 28 | 21 | 41 | M28L | N28LM36 | 89 | 28x2 | 250-310 |

NL-45 | M45X2 | 35 | 24 | 50 | M35L | N35LM45 | 137 | 35x3 | 400-500 |

NL-52 | M52X2 | 42 | 24 | 60 | M42L | N42LM52 | 216 | 42x3 | 500-600 |

S SERIE | |||||||||

NS-14 | M14X1.5 | 6 | 16.5 | 17 | M06S | N06SM14 | 17 | 6x2 | 35-45 |

NS-16 | M16X1.5 | 8 | 16.5 | 19 | M08S | N08SM16 | 20 | 8x1.5 | 55-60 |

NS-18 | M18X1.5 | 10 | 17.5 | 22 | M10S | N10SM18 | 31 | 10x1.5 | 70-80 |

NS-20 | M20X1.5 | 12 | 17.5 | 24 | M12S | N12SM20 | 34 | 12x1.5 | 85-100 |

NS-22 | M22X1.5 | 14 | 20.5 | 27 | M14S | N14SM22 | 53 | 14x2 | 110-135 |

NS-24 | M24X1.5 | 16 | 20.5 | 30 | M16S | N16SM24 | 66 | 16x1.5 | 120-150 |

NS-30 | M30X2 | 20 | 24 | 36 | M20S | N20SM30 | 102 | 20x2 | 200-250 |

NS-36 | M36X2 | 25 | 27 | 46 | M25S | N25SM36 | 202 | 25x2.5 | 340-400 |

NS-42 | M42X2 | 30 | 29 | 50 | M30S | N30SM42 | 219 | 30x3 | 480-500 |

NS-52 | M52X2 | 38 | 32.5 | 60 | M38S | N38SM52 | 339 | 38x4 | 600-850 |

NOTE: If order stainless steel please add SS after part no, ie NL-06SS.

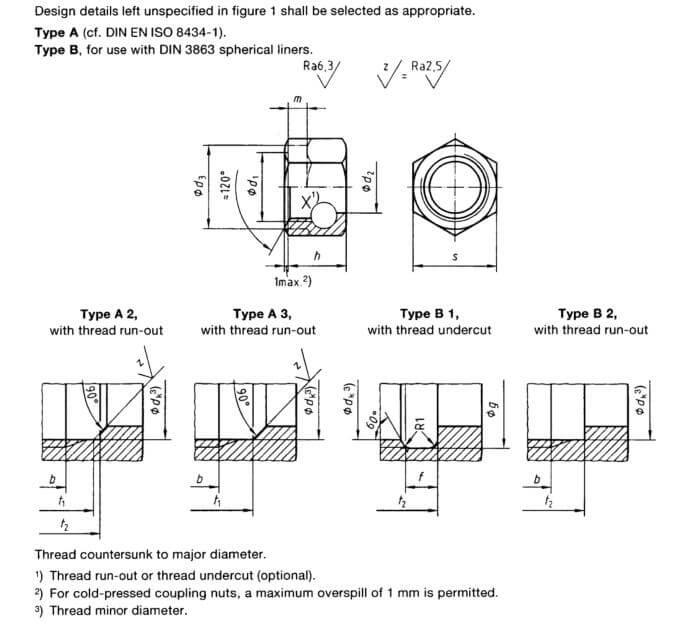

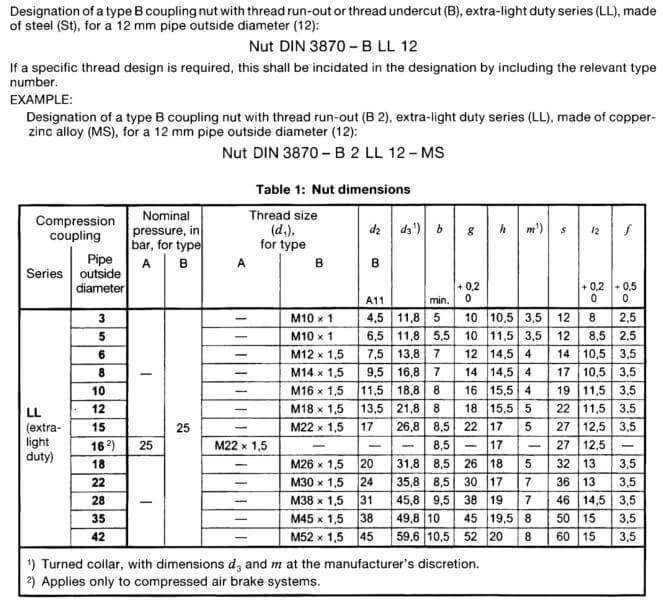

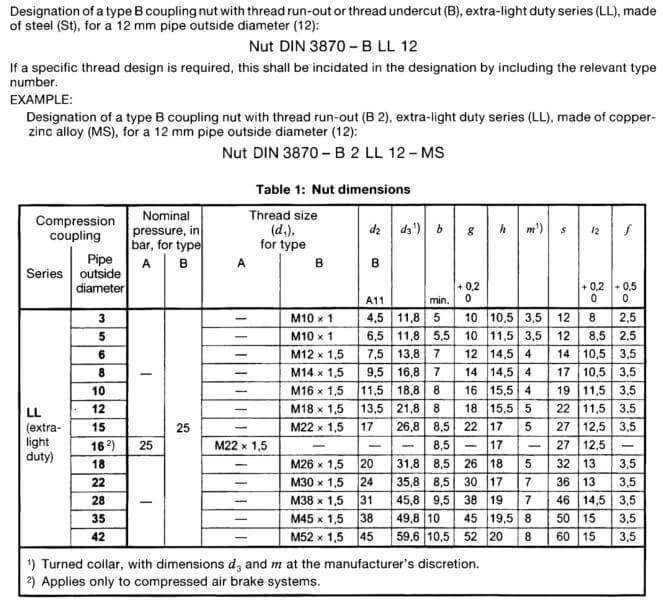

1. What is DIN 3870 tube nut Dimensions ?

Here is DIN 3870 LL series with Type A and Type B as follows:

2. What is difference tube nut between DIN 3870 vs ISO 8434-1?

DIN 3870 is coupling nut LL series for use with compression coupling, together with DIN EN ISO 8434-1.

ISO 8434-1 including LL, L and S series of tube nut for 24 degree cone tube connector.

Now ISO 8434-1 tube nut is most common in the trade business as standard parts.

3. Who is Chinese top manufacturer of DIN compression nut ISO tube nut?

With hot forging body of din tube nut

Automatic CNC machining lines of din tube nut

Meet ISO 8434-1 and DIN 3870 standard

Offer carbon steel and stainless steel

Fitsch can provide you the continuous growth support for business stronger.

1. What is DIN 3870 tube nut Dimensions ?

Here is DIN 3870 LL series with Type A and Type B as follows:

2. What is difference tube nut between DIN 3870 vs ISO 8434-1?

DIN 3870 is coupling nut LL series for use with compression coupling, together with DIN EN ISO 8434-1.

ISO 8434-1 including LL, L and S series of tube nut for 24 degree cone tube connector.

Now ISO 8434-1 tube nut is most common in the trade business as standard parts.

3. Who is Chinese top manufacturer of DIN compression nut ISO tube nut?

With hot forging body of din tube nut

Automatic CNC machining lines of din tube nut

Meet ISO 8434-1 and DIN 3870 standard

Offer carbon steel and stainless steel

Fitsch can provide you the continuous growth support for business stronger.