24 degree cone connector

Metric O-ring port

Straight

One wire braid hoses

| Availability: | |

|---|---|

| PDF Export | |

SAE Flare Flange: A Comprehensive Guide to SAE J518 Standard & 37° Non-Weld Connections

The SAE Flare Flange is a critical component in hydraulic and industrial systems, designed to ensure leak-proof, high-pressure connections without welding. Compliant with the SAE J518 standard, these flanges utilize a 37° flare angle for optimal sealing and durability. This article explores the technical specifications, applications, and benefits of SAE non-weld flare flange connections, focusing on their alignment with industry standards and SEO-friendly content for better search visibility.

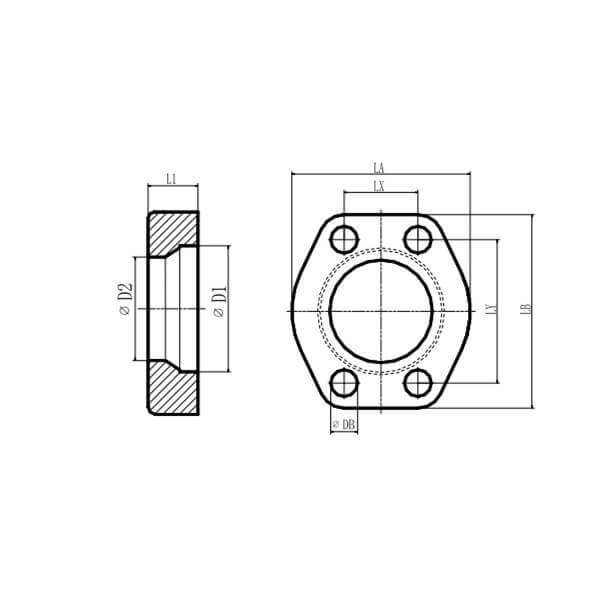

Catalog Size of Flare Flange Clamps

F37 − SAE 3000 / ISO 6162 -1

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LB | LX | LY | DB | Weight (Steel) kg/piece | W.P. bar |

| 1/2 | F37-308 | F37-308SS | 31 | 25.5 | 19 | 46 | 54 | 17.5 | 38.1 | 9 | 0.17 | 350 |

| 3/4 | F37-312 | F37-312SS | 39 | 30.5 | 20 | 52 | 65 | 22.3 | 47.6 | 11 | 0.21 | 350 |

| 1 | F37-316 | F37-316SS | 46 | 38.5 | 24 | 59 | 70.5 | 26.2 | 52.4 | 11 | 0.3 | 350 |

| 1 1/4 | F37-320 | F37-320SS | 51 | 42 1/2 | 22 | 73 | 80.5 | 30.2 | 58.7 | 11 | 0.46 | 280 |

| 1 1/2 | F37-324 | F37-324SS | 61 1/2 | 50.5 | 25 | 83 | 94.5 | 35.7 | 69.9 | 13.5 | 0.68 | 280 |

| 2 | F37-332 | F37-332SS | 71 1/2 | 60.5 | 33 | 97 | 101 1/2 | 42.9 | 77.8 | 13.5 | 0.98 | 280 |

| 2 1/2 | F37-340 | F37-340SS | 85 | 75.5 | 44 | 109 | 115.5 | 50.8 | 88.9 | 13.5 | 1.63 | 210 |

| 2 1/2 | F37-34073 | F37-34073SS | 85 | 73.5 | 44 | 109 | 115.5 | 50.8 | 88.9 | 13.5 | 1.87 | 210 |

| 3 | F37-348 | F37-348SS | 102 1/2 | 90.5 | 50 | 132 | 135 | 61.9 | 106.4 | 17 | 2.79 | 210 |

| 3 | F37-348909 | F37-48909SS | 105.5 | 90.7 | 50 | 132 | 135 | 61.9 | 106.4 | 17 | 3.47 | 210 |

| 4 | F37-364 | F37-364SS | 127.5 | 115.5 | 35 | 152 | 162 | 77.8 | 130.2 | 17 | 4.25 | 50 |

| 5 | F37-380125 | F37-80125SS | 152 1/2 | 125.5 | 45 | 181 | 184 | 92.1 | 152.4 | 17 | 4.68 | 50 |

| 5 | F37-380 | F37-380SS | 152 1/2 | 140.5 | 45 | 181 | 184 | 92.1 | 152.4 | 17 | 3.85 | 50 |

F37 − SAE 6000 / ISO 6162 -2

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LB | LX | LY | DB | Weight (Steel) kg/piece | W.P. bar |

| 1/2 | F37-608 | F37-608SS | 31 | 25.5 | 20 | 46 | 54 | 18.2 | 40.5 | 9 | 0.21 | 420 |

| 3/4 | F37-612 | F37-612SS | 39 | 30.5 | 24 | 60 | 71 | 23.8 | 50.8 | 11 | 0.42 | 420 |

| 1 | F37-616 | F37-616SS | 46 | 38.5 | 24 | 70 | 81 | 27.8 | 57.2 | 13 | 0.53 | 420 |

| 1 1/4 | F37-620 | F37-620SS | 51 | 42 1/2 | 30 | 78 | 95.5 | 31.8 | 66.6 | 15 | 0.92 | 420 |

| 1 1/2 | F37-624 | F37-624SS | 61 1/2 | 50.5 | 35 | 95 | 112 | 36.5 | 79.3 | 17 | 1 1/24 | 420 |

| 2 | F37-632 | F37-632SS | 71 1/2 | 60.5 | 40 | 114 | 133.5 | 44.5 | 96.8 | 22 | 2.44 | 420 |

| 2 1/2 | F37-640 | F37-640SS | 85 | 75.5 | 50 | 150 | 175 | 58.7 | 123.8 | 26 | 5.69 | 420 |

| 2 1/2 | F37-64073 | F37-64073SS | 85 | 73.5 | 50 | 150 | 175 | 58.7 | 123.8 | 26 | 6.46 | 420 |

| 3 | F37-648 | F37-648SS | 105.5 | 90.7 | 50 | 178 | 215 | 71.4 | 152.4 | 32 | 7.8 | 420 |

SAE J518 Compliance

The SAE J518 standard defines specifications for split flange clamp halves, flanged heads, and port designs. These components are engineered to withstand pressures ranging from 3.5 MPa to 35 MPa (Code 61) and up to 42 MPa (Code 62) in industrial hydraulic systems.

Materials include high-grade steel for flanged heads and SAE 5-grade bolts to ensure structural integrity under stress.

37° Flare Angle Design

The 37° flare ensures a secure, self-centering seal when paired with O-rings or gaskets. This design minimizes leakage risks in high-pressure environments, such as oil and gas pipelines or heavy machinery.

Non-Weld Connection Advantages

SAE non-weld flare flanges (e.g., split flange clamps) eliminate the need for welding, reducing installation time and maintenance costs. They are ideal for retrofitting existing systems or applications requiring frequent disassembly.

SAE flare flanges are widely used in:

Hydraulic Systems: For connecting tubes, pipes, and hoses in construction equipment and agricultural machinery.

Industrial Fluid Transfer: In chemical plants, oil refineries, and power generation facilities.

Aerospace and Automotive: High-pressure fuel lines and brake systems.

Alignment: Ensure proper alignment of split flange halves to avoid uneven stress distribution.

Torque Specifications: Follow SAE-recommended bolt tightening sequences to prevent over-compression.

Material Compatibility: Use O-rings compliant with SAE J120 to resist chemical degradation.

Durability: Robust steel construction and corrosion-resistant coatings extend service life.

Versatility: Compatible with diverse media, including hydraulic fluids, fuels, and gases.

Cost-Efficiency: Reduced downtime and maintenance costs compared to welded alternatives.

SAE flare flanges adhering to the J518 standard offer unmatched reliability for high-pressure systems. Their 37° flare angle and non-weld design make them a preferred choice across industries. For engineers and procurement specialists, understanding these specifications ensures optimal system performance and compliance.

SAE Flare Flange: A Comprehensive Guide to SAE J518 Standard & 37° Non-Weld Connections

The SAE Flare Flange is a critical component in hydraulic and industrial systems, designed to ensure leak-proof, high-pressure connections without welding. Compliant with the SAE J518 standard, these flanges utilize a 37° flare angle for optimal sealing and durability. This article explores the technical specifications, applications, and benefits of SAE non-weld flare flange connections, focusing on their alignment with industry standards and SEO-friendly content for better search visibility.

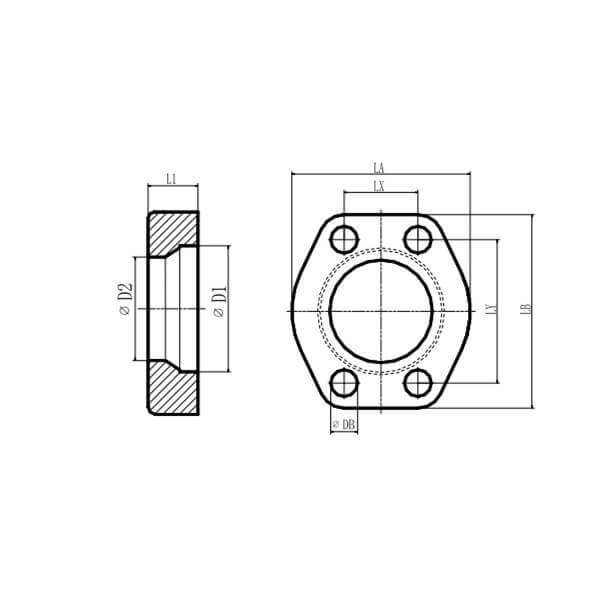

Catalog Size of Flare Flange Clamps

F37 − SAE 3000 / ISO 6162 -1

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LB | LX | LY | DB | Weight (Steel) kg/piece | W.P. bar |

| 1/2 | F37-308 | F37-308SS | 31 | 25.5 | 19 | 46 | 54 | 17.5 | 38.1 | 9 | 0.17 | 350 |

| 3/4 | F37-312 | F37-312SS | 39 | 30.5 | 20 | 52 | 65 | 22.3 | 47.6 | 11 | 0.21 | 350 |

| 1 | F37-316 | F37-316SS | 46 | 38.5 | 24 | 59 | 70.5 | 26.2 | 52.4 | 11 | 0.3 | 350 |

| 1 1/4 | F37-320 | F37-320SS | 51 | 42 1/2 | 22 | 73 | 80.5 | 30.2 | 58.7 | 11 | 0.46 | 280 |

| 1 1/2 | F37-324 | F37-324SS | 61 1/2 | 50.5 | 25 | 83 | 94.5 | 35.7 | 69.9 | 13.5 | 0.68 | 280 |

| 2 | F37-332 | F37-332SS | 71 1/2 | 60.5 | 33 | 97 | 101 1/2 | 42.9 | 77.8 | 13.5 | 0.98 | 280 |

| 2 1/2 | F37-340 | F37-340SS | 85 | 75.5 | 44 | 109 | 115.5 | 50.8 | 88.9 | 13.5 | 1.63 | 210 |

| 2 1/2 | F37-34073 | F37-34073SS | 85 | 73.5 | 44 | 109 | 115.5 | 50.8 | 88.9 | 13.5 | 1.87 | 210 |

| 3 | F37-348 | F37-348SS | 102 1/2 | 90.5 | 50 | 132 | 135 | 61.9 | 106.4 | 17 | 2.79 | 210 |

| 3 | F37-348909 | F37-48909SS | 105.5 | 90.7 | 50 | 132 | 135 | 61.9 | 106.4 | 17 | 3.47 | 210 |

| 4 | F37-364 | F37-364SS | 127.5 | 115.5 | 35 | 152 | 162 | 77.8 | 130.2 | 17 | 4.25 | 50 |

| 5 | F37-380125 | F37-80125SS | 152 1/2 | 125.5 | 45 | 181 | 184 | 92.1 | 152.4 | 17 | 4.68 | 50 |

| 5 | F37-380 | F37-380SS | 152 1/2 | 140.5 | 45 | 181 | 184 | 92.1 | 152.4 | 17 | 3.85 | 50 |

F37 − SAE 6000 / ISO 6162 -2

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LB | LX | LY | DB | Weight (Steel) kg/piece | W.P. bar |

| 1/2 | F37-608 | F37-608SS | 31 | 25.5 | 20 | 46 | 54 | 18.2 | 40.5 | 9 | 0.21 | 420 |

| 3/4 | F37-612 | F37-612SS | 39 | 30.5 | 24 | 60 | 71 | 23.8 | 50.8 | 11 | 0.42 | 420 |

| 1 | F37-616 | F37-616SS | 46 | 38.5 | 24 | 70 | 81 | 27.8 | 57.2 | 13 | 0.53 | 420 |

| 1 1/4 | F37-620 | F37-620SS | 51 | 42 1/2 | 30 | 78 | 95.5 | 31.8 | 66.6 | 15 | 0.92 | 420 |

| 1 1/2 | F37-624 | F37-624SS | 61 1/2 | 50.5 | 35 | 95 | 112 | 36.5 | 79.3 | 17 | 1 1/24 | 420 |

| 2 | F37-632 | F37-632SS | 71 1/2 | 60.5 | 40 | 114 | 133.5 | 44.5 | 96.8 | 22 | 2.44 | 420 |

| 2 1/2 | F37-640 | F37-640SS | 85 | 75.5 | 50 | 150 | 175 | 58.7 | 123.8 | 26 | 5.69 | 420 |

| 2 1/2 | F37-64073 | F37-64073SS | 85 | 73.5 | 50 | 150 | 175 | 58.7 | 123.8 | 26 | 6.46 | 420 |

| 3 | F37-648 | F37-648SS | 105.5 | 90.7 | 50 | 178 | 215 | 71.4 | 152.4 | 32 | 7.8 | 420 |

SAE J518 Compliance

The SAE J518 standard defines specifications for split flange clamp halves, flanged heads, and port designs. These components are engineered to withstand pressures ranging from 3.5 MPa to 35 MPa (Code 61) and up to 42 MPa (Code 62) in industrial hydraulic systems.

Materials include high-grade steel for flanged heads and SAE 5-grade bolts to ensure structural integrity under stress.

37° Flare Angle Design

The 37° flare ensures a secure, self-centering seal when paired with O-rings or gaskets. This design minimizes leakage risks in high-pressure environments, such as oil and gas pipelines or heavy machinery.

Non-Weld Connection Advantages

SAE non-weld flare flanges (e.g., split flange clamps) eliminate the need for welding, reducing installation time and maintenance costs. They are ideal for retrofitting existing systems or applications requiring frequent disassembly.

SAE flare flanges are widely used in:

Hydraulic Systems: For connecting tubes, pipes, and hoses in construction equipment and agricultural machinery.

Industrial Fluid Transfer: In chemical plants, oil refineries, and power generation facilities.

Aerospace and Automotive: High-pressure fuel lines and brake systems.

Alignment: Ensure proper alignment of split flange halves to avoid uneven stress distribution.

Torque Specifications: Follow SAE-recommended bolt tightening sequences to prevent over-compression.

Material Compatibility: Use O-rings compliant with SAE J120 to resist chemical degradation.

Durability: Robust steel construction and corrosion-resistant coatings extend service life.

Versatility: Compatible with diverse media, including hydraulic fluids, fuels, and gases.

Cost-Efficiency: Reduced downtime and maintenance costs compared to welded alternatives.

SAE flare flanges adhering to the J518 standard offer unmatched reliability for high-pressure systems. Their 37° flare angle and non-weld design make them a preferred choice across industries. For engineers and procurement specialists, understanding these specifications ensures optimal system performance and compliance.