JIC 37 degree cone end

Metric O-ring port

Straight

| Availability: | |

|---|---|

| PDF Export | |

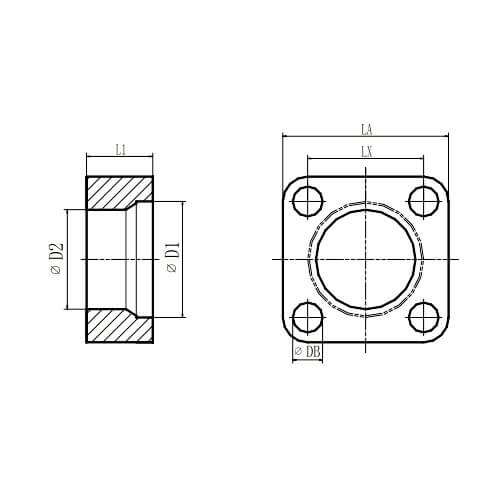

ISO 6164 Flare Flange Clamps are specialized hydraulic connectors designed for high-pressure systems in industries such as marine, heavy machinery, and offshore engineering. These clamps feature a four-screw, one-piece square flange design standardized under ISO 6164, ensuring leak-free performance and compatibility with 1" to 4" pipelines.

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LX | DB | Weight (Steel) kg/piece | W.P. bar |

| 1 | F37-416 | F37-416SS | 46 | 38.5 | 25 | 65 | 43.8 | 11 | 0.47 | 400 |

| 1 1/4 | F37-420 | F37-420SS | 51 | 42 1/2 | 30 | 75 | 51.6 | 13 | 0.74 | 400 |

| 1 1/2 | F37-424 | F37-424SS | 61 1/2 | 50.5 | 36 | 90 | 60.1 | 17 | 1.26 | 400 |

| 2 | F37-432 | F37-432SS | 71 1/2 | 60.5 | 40 | 100 | 69.3 | 18 | 1.8 | 400 |

| 2 1/2 | F37-440 | F37-440SS | 85 | 75.5 | 50 | 120 | 83.4 | 22 | 3 | 400 |

| 2 1/2 | F37-44073 | F37-44073SS | 85 | 73.5 | 50 | 120 | 83.4 | 22 | 3.1 | 400 |

| 3 | F37-448 | F37-448SS | 102 1/2 | 90.5 | 52 | 150 | 102 1/2 | 26 | 5.4 | 400 |

| 3 | F37-448909 | F37-448909SS | 105.5 | 90.7 | 52 | 150 | 102 1/2 | 26 | 5.29 | 400 |

| 4 | F37-464 | F37-464SS | 128 | 115.7 | 70 | 180 | 123.7 | 32 | 10.2 | 400 |

Material Options: Available in carbon steel (ASTM A105) or stainless steel (ASTM A182) for corrosion resistance in harsh conditions.

Flare Interface: The 37° flared tube end ensures smooth, secure sealing with O-ring grooves for soft-seal inserts, eliminating welding-related risks like deformation or porosity .

Split-Clamp Mechanism: Simplifies installation and maintenance without disassembling pipelines, ideal for confined spaces .

Complies with ISO 6164, SAE J518 Code 61/62, and CCS/ABS/DNV marine certifications .

Rated for pressures up to 400 bar (5800 psi), tested for hydraulic fluid compatibility and thermal stability .

Shipbuilding: Approved for marine hydraulic systems (CCS-certified models).

Industrial Machinery: Used in steelworks, mining equipment, and hydraulic test stations.

Energy Sector: Deployed in offshore oil/gas platforms due to corrosion-resistant stainless steel variants

Global Standards Compliance: All products meet ISO 6164 and SAE specifications for interoperability.

Reduced Downtime: Non-welded design cuts installation time by 50% compared to traditional methods.

Technical Support: Free CAD drawings, pressure-drop calculations, and 24/7 engineering assistance.

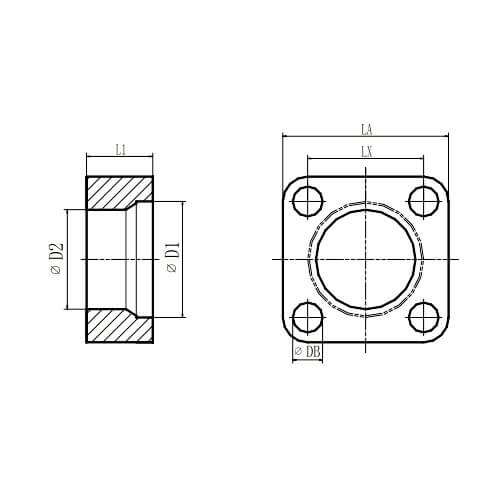

ISO 6164 Flare Flange Clamps are specialized hydraulic connectors designed for high-pressure systems in industries such as marine, heavy machinery, and offshore engineering. These clamps feature a four-screw, one-piece square flange design standardized under ISO 6164, ensuring leak-free performance and compatibility with 1" to 4" pipelines.

| Flange Size Inch | Steel Part No. | Stainless Part No. | D1 | D2 | L1 | LA | LX | DB | Weight (Steel) kg/piece | W.P. bar |

| 1 | F37-416 | F37-416SS | 46 | 38.5 | 25 | 65 | 43.8 | 11 | 0.47 | 400 |

| 1 1/4 | F37-420 | F37-420SS | 51 | 42 1/2 | 30 | 75 | 51.6 | 13 | 0.74 | 400 |

| 1 1/2 | F37-424 | F37-424SS | 61 1/2 | 50.5 | 36 | 90 | 60.1 | 17 | 1.26 | 400 |

| 2 | F37-432 | F37-432SS | 71 1/2 | 60.5 | 40 | 100 | 69.3 | 18 | 1.8 | 400 |

| 2 1/2 | F37-440 | F37-440SS | 85 | 75.5 | 50 | 120 | 83.4 | 22 | 3 | 400 |

| 2 1/2 | F37-44073 | F37-44073SS | 85 | 73.5 | 50 | 120 | 83.4 | 22 | 3.1 | 400 |

| 3 | F37-448 | F37-448SS | 102 1/2 | 90.5 | 52 | 150 | 102 1/2 | 26 | 5.4 | 400 |

| 3 | F37-448909 | F37-448909SS | 105.5 | 90.7 | 52 | 150 | 102 1/2 | 26 | 5.29 | 400 |

| 4 | F37-464 | F37-464SS | 128 | 115.7 | 70 | 180 | 123.7 | 32 | 10.2 | 400 |

Material Options: Available in carbon steel (ASTM A105) or stainless steel (ASTM A182) for corrosion resistance in harsh conditions.

Flare Interface: The 37° flared tube end ensures smooth, secure sealing with O-ring grooves for soft-seal inserts, eliminating welding-related risks like deformation or porosity .

Split-Clamp Mechanism: Simplifies installation and maintenance without disassembling pipelines, ideal for confined spaces .

Complies with ISO 6164, SAE J518 Code 61/62, and CCS/ABS/DNV marine certifications .

Rated for pressures up to 400 bar (5800 psi), tested for hydraulic fluid compatibility and thermal stability .

Shipbuilding: Approved for marine hydraulic systems (CCS-certified models).

Industrial Machinery: Used in steelworks, mining equipment, and hydraulic test stations.

Energy Sector: Deployed in offshore oil/gas platforms due to corrosion-resistant stainless steel variants

Global Standards Compliance: All products meet ISO 6164 and SAE specifications for interoperability.

Reduced Downtime: Non-welded design cuts installation time by 50% compared to traditional methods.

Technical Support: Free CAD drawings, pressure-drop calculations, and 24/7 engineering assistance.