Product Overview

Extrusion anchors are key fixed - end anchor devices in prestressed anchorage systems. By using an extrusion press to crimp the extrusion sleeve onto the steel strand (or prestressed tendon), they rely on the wrap - around anchoring principle to achieve reliable fixing of prestressed tendons. Usually pre - embedded in concrete, after the concrete reaches the design strength, they work with the tension end for tensioning operations. They are suitable for scenarios where the design stress at the end of components is high, the end space is limited, and post - tensioned prestress needs to be directly transmitted to the structural end face. They are widely used in infrastructure projects such as highway and railway bridges, urban interchanges, high - rise buildings, and water conservancy and hydropower dams.

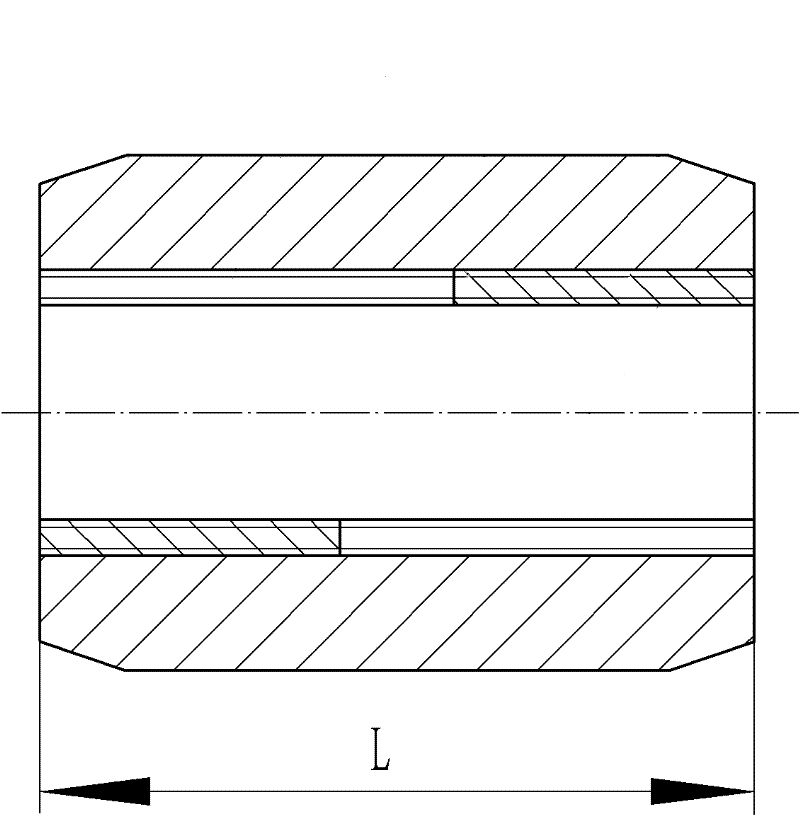

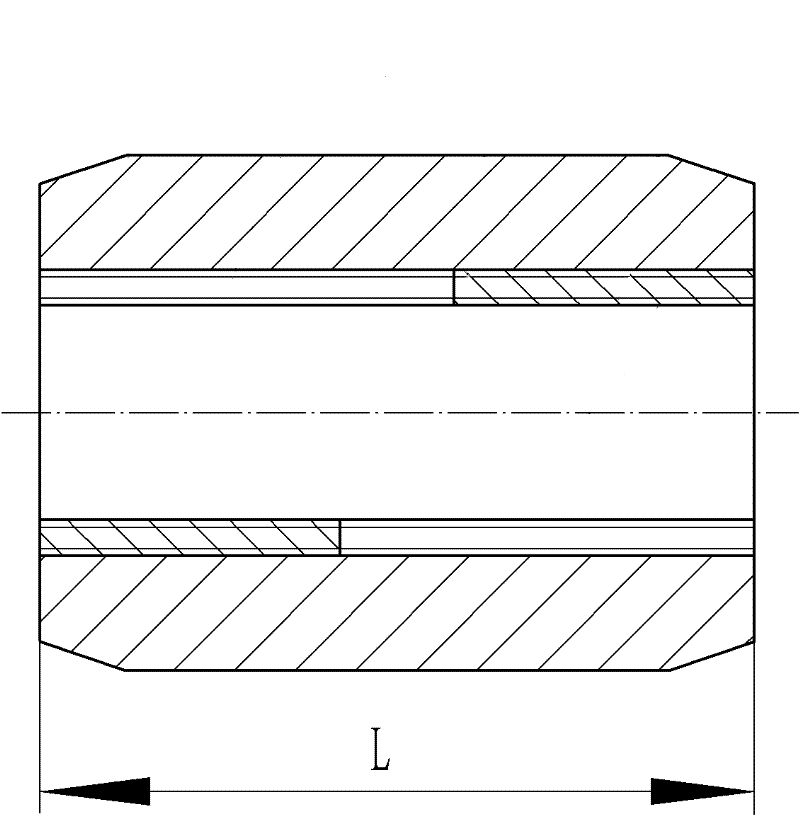

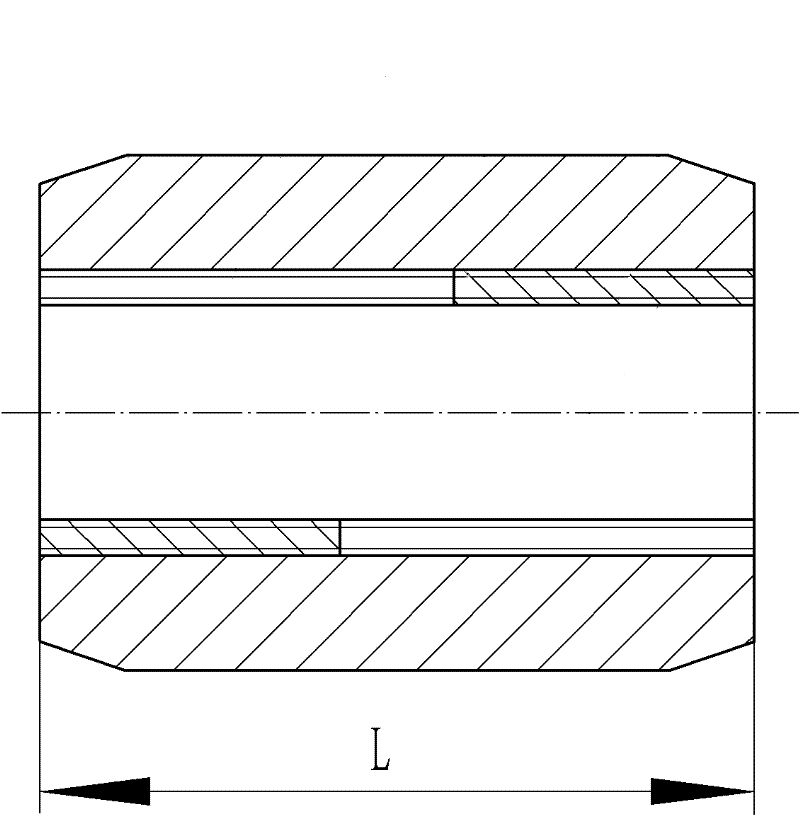

L (mm) | D (mm) | Part No |

35 | 55 | JYM1 |

37 | 58 | JYM2 |

91 | 47 | JYM3 |

Core Advantages

Material and Performance

Made of high - quality alloy steel (20CrMnTi).It has excellent tensile strength, fatigue resistance, and anti - wear and anti - deformation capabilities, ensuring stable anchorage performance under heavy - load working conditions.

Anchoring Efficiency

With optimized geometric design, after installation, it transfers loads seamlessly, greatly reducing stress concentration. It is suitable for bridges, floor slabs, and civil structures, helping to accurately apply and maintain prestress for a long time, and improving the overall safety and durability of the structure.

Adaptability and Expansion

It can match various specifications of prestressed steel strands (such as matching common steel strands of 12.7 - 15.7mm). It covers different strength grades (1860MPA - 2000Mpa for steel strands; 1670Mpa for high - strength steel wire bundles). It supports customized coatings to cope with harsh environments such as humidity and corrosion, expanding the application scenarios.