24 degree cone connector

Metric O-ring port

Straight

One wire braid hoses

| Availability: | |

|---|---|

| PDF Export | |

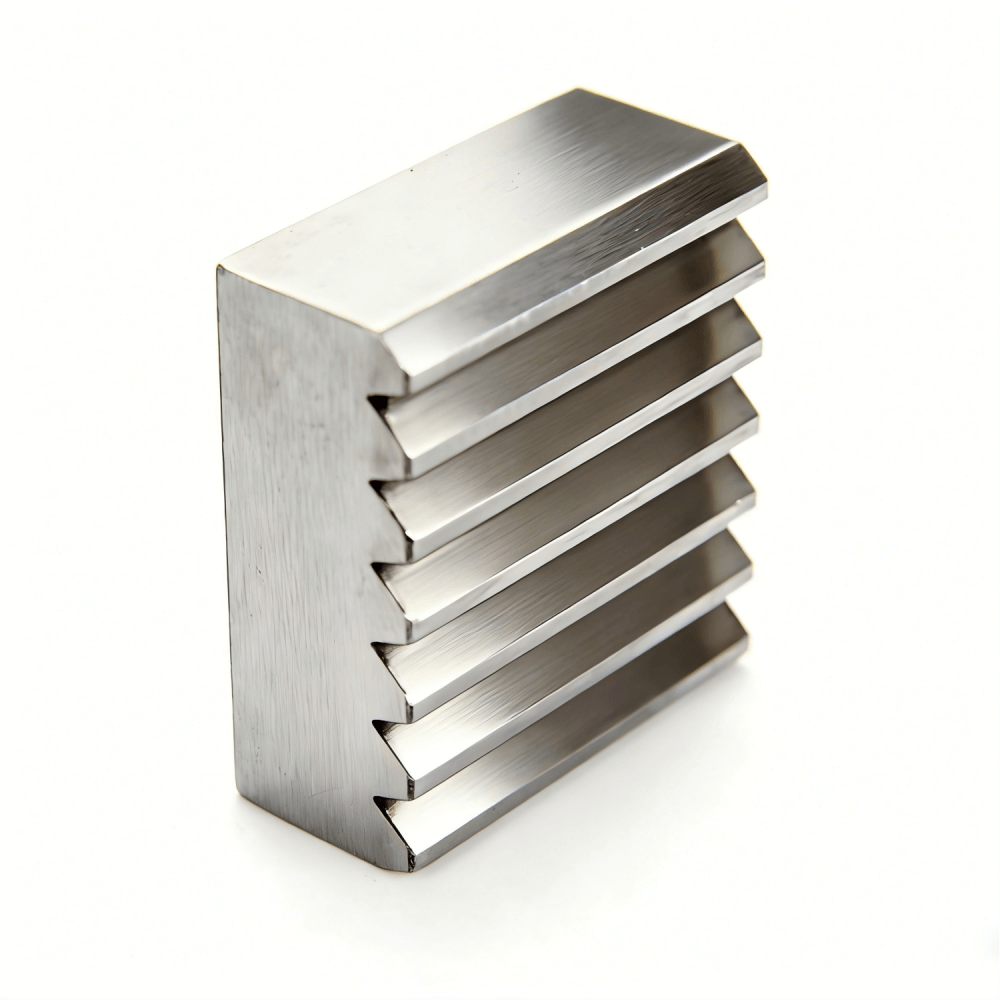

High-Performance Toothed Rack Rails & Rack Gears for Robust Linear Motion

Upgrade your drive systems with our precision-engineered toothed rack rails and rack gears, designed to deliver reliable, high-strength linear motion for demanding industrial applications. Manufactured from high-grade Q345 material and featuring a universal 60-degree tooth design, these components ensure smooth power transmission,

excellent durability, and long-term performance in rack and pinion systems.

Product Specifications & Key Details:

Material: High-Strength Q345 Steel. This low-alloy structural steel offers superior yield strength, excellent toughness, and outstanding wear resistance compared to standard carbon steel, making it ideal for high-load and high-cycle applications.

Standard Size (Long Rack): 40mm (Height) x 18.5mm (Width) x 710mm Length. This linear rack is perfect for creating extended travel axes in automation and machinery.

Standard Size (Short Rack / Gear Segment): 40mm (Height) x 18.5mm (Width) x 44mm Length. This shorter rack gear piece is versatile for use in compact assemblies, test setups, or as a replacement segment.

Tooth Profile: 60-Degree Involute Tooth Design. This standardized tooth angle ensures optimal meshing with compatible pinion gears, providing smooth operation, minimal backlash, high efficiency, and reduced noise in motion systems.

Compatibility: Designed for seamless integration with standard rack and pinion drives, linear motion systems, and various gearing applications.

Primary Applications:

Our racks are essential components across numerous industries requiring precise linear movement:

CNC Machinery & CNC Routers: For accurate X, Y, and Z-axis movement.

Industrial Automation & Robotics: As a core part of linear actuators and gantry systems.

3D Printers & DIY CNC Projects: Especially in larger-format or high-precision custom builds.

Material Handling Systems: Including sliding gates, lifts, and conveyor drives.

General Machinery & Prototyping: Wherever a reliable linear gear or gear rack is needed.

Why Choose Our Toothed Racks & Gears?

Superior Durability: The Q345 steel construction provides exceptional strength and fatigue resistance, outperforming standard racks in harsh environments and under continuous use.

Precision Engineering: The consistent 60-degree tooth profile guarantees smooth and precise engagement with pinions, critical for achieving high positional accuracy in linear motion applications.

Ready-to-Install: Supplied as precision-machined components, our racks are ready for easy integration into your existing or new linear drive system.

Versatility: Available in both long (for travel) and short (for modular or repair use) lengths, offering flexibility for various project requirements, from large-scale industrial machines to compact 3D printer upgrades.

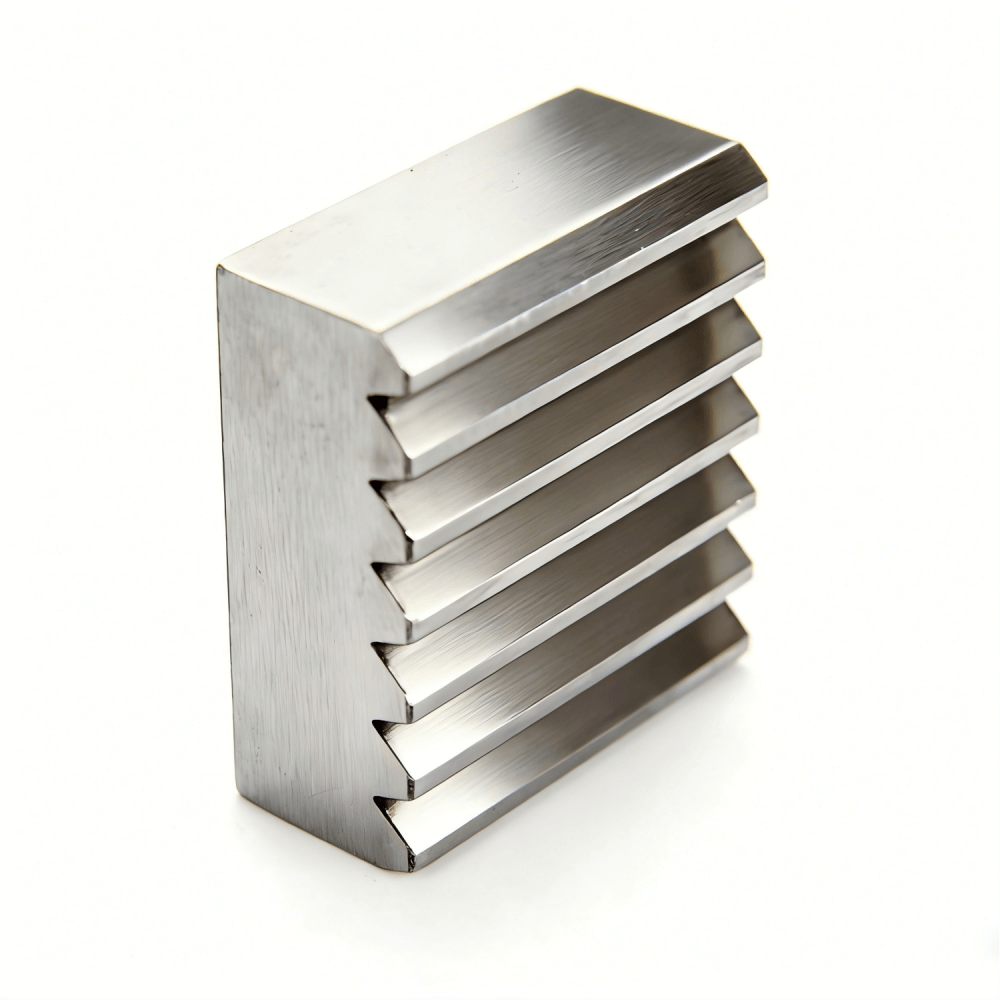

High-Performance Toothed Rack Rails & Rack Gears for Robust Linear Motion

Upgrade your drive systems with our precision-engineered toothed rack rails and rack gears, designed to deliver reliable, high-strength linear motion for demanding industrial applications. Manufactured from high-grade Q345 material and featuring a universal 60-degree tooth design, these components ensure smooth power transmission,

excellent durability, and long-term performance in rack and pinion systems.

Product Specifications & Key Details:

Material: High-Strength Q345 Steel. This low-alloy structural steel offers superior yield strength, excellent toughness, and outstanding wear resistance compared to standard carbon steel, making it ideal for high-load and high-cycle applications.

Standard Size (Long Rack): 40mm (Height) x 18.5mm (Width) x 710mm Length. This linear rack is perfect for creating extended travel axes in automation and machinery.

Standard Size (Short Rack / Gear Segment): 40mm (Height) x 18.5mm (Width) x 44mm Length. This shorter rack gear piece is versatile for use in compact assemblies, test setups, or as a replacement segment.

Tooth Profile: 60-Degree Involute Tooth Design. This standardized tooth angle ensures optimal meshing with compatible pinion gears, providing smooth operation, minimal backlash, high efficiency, and reduced noise in motion systems.

Compatibility: Designed for seamless integration with standard rack and pinion drives, linear motion systems, and various gearing applications.

Primary Applications:

Our racks are essential components across numerous industries requiring precise linear movement:

CNC Machinery & CNC Routers: For accurate X, Y, and Z-axis movement.

Industrial Automation & Robotics: As a core part of linear actuators and gantry systems.

3D Printers & DIY CNC Projects: Especially in larger-format or high-precision custom builds.

Material Handling Systems: Including sliding gates, lifts, and conveyor drives.

General Machinery & Prototyping: Wherever a reliable linear gear or gear rack is needed.

Why Choose Our Toothed Racks & Gears?

Superior Durability: The Q345 steel construction provides exceptional strength and fatigue resistance, outperforming standard racks in harsh environments and under continuous use.

Precision Engineering: The consistent 60-degree tooth profile guarantees smooth and precise engagement with pinions, critical for achieving high positional accuracy in linear motion applications.

Ready-to-Install: Supplied as precision-machined components, our racks are ready for easy integration into your existing or new linear drive system.

Versatility: Available in both long (for travel) and short (for modular or repair use) lengths, offering flexibility for various project requirements, from large-scale industrial machines to compact 3D printer upgrades.